General Definitions:

- IBC (International Building Code, USA):

- Section 909 mandates smoke control systems for enclosed office spaces larger than 50,000 sq. ft. (4,645 m²) or buildings containing windowless areas, designed to manage smoke movement, ensuring safe evacuation and firefighter access.

- BSL (Building Standard Law, Japan):

- Articles 17 and 35 require smoke control systems for large office buildings and high-rise business complexes to effectively prevent smoke spread and ensure occupant safety.

Comparison Table:

| Criterion | IBC (USA) | BSL (Japan) |

| Smoke Control System Requirement | Required for enclosed office spaces > 50,000 sq. ft. (4,645 m²) or windowless spaces | Required for large office buildings and high-rise business complexes |

| Basis for Requirement | Office area size, presence of windowless areas | Building size, height, and complexity of occupancy |

| Scope of Application | Clearly defined area-based criteria | Broader criteria focused on building scale and complexity |

| Compliance and Enforcement | Enforced by local authority via inspections referencing IBC 909 | Enforced through standardized national inspections under Articles 17, 35 |

| Flexibility and Adaptability | Provides prescriptive and performance-based options | Performance-based standards allowing adaptive implementations |

| Testing and Certification | Compliance with NFPA 92 and other relevant standards | Compliance with Japanese Industrial Standards (JIS) |

Key Differences:

- IBC: Clearly defined spatial requirements and specific conditions (large or windowless areas).

- BSL: General criteria emphasizing overall building scale, height, and occupancy complexity.

Case Study:

5-Story Office Building

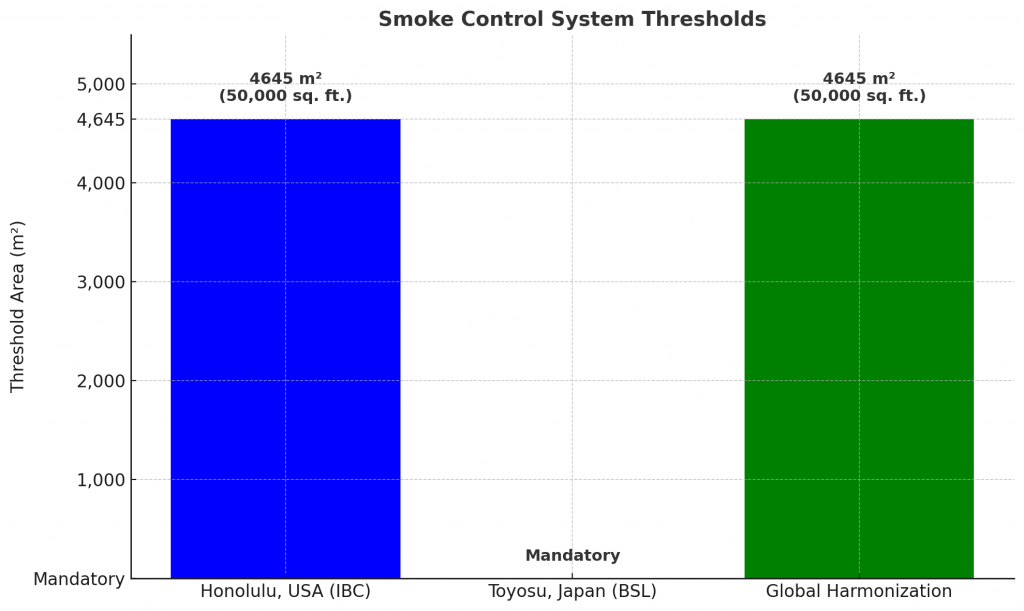

- Honolulu, USA (IBC):

- Smoke Control System: Required if enclosed office space exceeds 50,000 sq. ft. (4,645 m²) or contains windowless areas.

- Toyosu, Japan (BSL):

- Smoke Control System: Required for large office building/high-rise business complex categorization.

Global Approach:

- Unified Smoke Control Standards:

- Develop globally recognized standards defining explicit thresholds and conditions for smoke control systems.

- Performance and Risk-Based Integration:

- Adopt flexible criteria combining specific spatial requirements (IBC) and broader occupancy complexity (BSL).

- International Certification and Testing Standards:

- Standardize testing and certification protocols internationally to ensure uniform compliance.

- Collaborative International Framework:

- Regularly conduct global forums to update and harmonize standards, incorporating international best practices.

- Educational Initiatives:

- Provide comprehensive training and awareness campaigns for global construction professionals to ensure consistent application of harmonized smoke control standards.

Step-by-step calculations used to determine the maximum allowable leakage areas for a 5-story, Group B occupancy building with 10,000 ft² per floor, based on IBC 2018 [F] Section 909.5 and the leakage area ratios listed therein.

Input Parameters

- Number of stories (floors): 5

- Area per floor: 10,000 ft²

- Story height (typical): 12 ft

- Stair enclosure size: 10 ft × 20 ft

- Shaft size (elevator/mechanical): 10 ft × 10 ft

- Total floor/roof areas: 5 floors + 1 roof = 6 slabs

Step 1: Wall Area Calculation

Assumption:

Floor plate is square-shaped:

- Side length = √10,000 ft² = 100 ft

- Perimeter = 4 × 100 ft = 400 ft

- Wall area per floor = 400 ft × 12 ft = 4,800 ft²

- For 5 stories: 4,800 ft² × 5 = 24,000 ft²

Apply leakage ratio:

- Leakage Ratio = 0.00100

- Max leakage area = 24,000 ft² × 0.00100 = 24.00 ft² (≈ 2.23 m²)

Step 2: Stair Enclosure Wall Area

Assumption:

Stair enclosure perimeter:

- (10 ft + 20 ft) × 2 = 60 ft

- Height = 12 ft/story × 5 = 60 ft

- Wall area = 60 ft × 60 ft = 3,600 ft²

Apply leakage ratio:

- Leakage Ratio = 0.00035

- Max leakage area = 3,600 ft² × 0.00035 = 1.26 ft² (≈ 0.12 m²)

Step 3: Shaft Wall Area

Assumption:

Shaft perimeter = 4 × 10 ft = 40 ft

- Height = 60 ft

- Wall area = 40 ft × 60 ft = 2,400 ft²

Apply leakage ratio:

- Leakage Ratio = 0.00150

- Max leakage area = 2,400 ft² × 0.00150 = 3.60 ft² (≈ 0.33 m²)

Step 4: Floor and Roof Area

- Floor/roof area = 10,000 ft² × (5 floors + 1 roof) = 60,000 ft²

Apply leakage ratio:

- Leakage Ratio = 0.00050

- Max leakage area = 60,000 ft² × 0.00050 = 30.00 ft² (≈ 2.79 m²)

Summary Table

| Element | Leakage Ratio | Area Used (ft²) | Max Leakage (ft²) | Max Leakage (m²) |

| Walls | 0.00100 | 24,000 | 24.00 | 2.23 |

| Interior Stairs | 0.00035 | 3,600 | 1.26 | 0.12 |

| Shafts | 0.00150 | 2,400 | 3.60 | 0.33 |

| Floors + Roof | 0.00050 | 60,000 | 30.00 | 2.79 |

入力パラメータ

- 階数:5階建て

- 各階の面積:10,000 ft²(約929 m²)

- 階高(仮定):12フィート(約3.66 m)

- 階段室サイズ:10 ft × 20 ft(約3 m × 6 m)

- シャフトサイズ(エレベーター・設備):10 ft × 10 ft(約3 m × 3 m)

- 床と屋根の合計スラブ数:5階+1屋根 = 6枚

ステップ1:外壁面積の計算

仮定:

- 床の形状は正方形 → 一辺 = √10,000 ft² = 100 ft(約30.5 m)

- 外周 = 4 × 100 ft = 400 ft

- 各階の壁面積 = 400 ft × 12 ft = 4,800 ft²

- 合計(5階分)= 4,800 ft² × 5 = 24,000 ft²

漏洩面積の計算:

- 漏洩係数:0.00100

- 最大漏洩面積 = 24,000 × 0.00100 = 24.00 ft²(約2.23 m²)

ステップ2:階段室の壁面積

仮定:

- 階段室の外周 = (10 ft + 20 ft) × 2 = 60 ft

- 高さ = 12 ft × 5階 = 60 ft

- 面積 = 60 ft × 60 ft = 3,600 ft²

漏洩面積の計算:

- 漏洩係数:0.00035

- 最大漏洩面積 = 3,600 × 0.00035 = 1.26 ft²(約0.12 m²)

ステップ3:シャフトの壁面積

仮定:

- 外周 = 10 ft × 4 = 40 ft

- 高さ = 60 ft

- 面積 = 40 ft × 60 ft = 2,400 ft²

漏洩面積の計算:

- 漏洩係数:0.00150

- 最大漏洩面積 = 2,400 × 0.00150 = 3.60 ft²(約0.33 m²)

ステップ4:床および屋根の面積

- 総面積 = 10,000 ft² × 6(5階+1屋根) = 60,000 ft²

漏洩面積の計算:

- 漏洩係数:0.00050

- 最大漏洩面積 = 60,000 × 0.00050 = 30.00 ft²(約2.79 m²)

まとめ表

| 区画要素 | 漏洩係数 | 使用面積(ft²) | 最大漏洩面積(ft²) | 最大漏洩面積(m²) |

|---|---|---|---|---|

| 外壁 | 0.00100 | 24,000 | 24.00 | 2.23 |

| 階段室(内部避難経路) | 0.00035 | 3,600 | 1.26 | 0.12 |

| シャフト(機械・昇降路) | 0.00150 | 2,400 | 3.60 | 0.33 |

| 床・屋根 | 0.00050 | 60,000 | 30.00 | 2.79 |

Calculations Means and Methods Table:

| Tool / Method | Purpose | When Used |

|---|---|---|

| Code-based math (IBC) | Estimate max leakage area | Design phase |

| Air leakage testing | Verify leakage with actual equipment | Post-construction (optional) |

| CFD / airflow software | Simulate pressure and smoke movement | Complex designs |

| Product specifications | Select components that limit leakage | During detailing & specs |

Although the Building Standard Law (BSL) does not specify detailed leakage area calculations like those found in the IBC, it places strong emphasis on smoke compartmentalization, the construction of robust smoke barriers, and the implementation of effective smoke control systems that are appropriate to the building’s design and occupancy. Consulting with local experts and authorities is essential to ensure that all specific regulatory requirements are properly addressed for your building project in Japan.

建築基準法(BSL)は、IBCのような明確な漏洩面積の計算方法を定めているわけではありませんが、建物の設計および用途に応じたスモーク・コンパートメンテーション(防煙区画)、堅牢なバリア(区画壁)の構築、および効果的な排煙制御システムの導入を重視しています。

日本での建築プロジェクトにおいては、すべての具体的な法的要件を確実に満たすために、地元の専門家や行政当局との連携が不可欠です。